HVO (Hydrogenated Vegetable Oil) Case Study

The Task

LCM have a longstanding working relationship with a London data centre which has included the PPM (Planned Preventative Maintenance) of the existing fuel and fuel infrastructure. After consultation with the customer, it was decided that switching to HVO was the best option for them. The HVO Switchover enables them to meet their green targets and provides better-performing products which do not deteriorate, and meet their scope 1 emissions control needs – unlike the standard B7 fossil fuel.

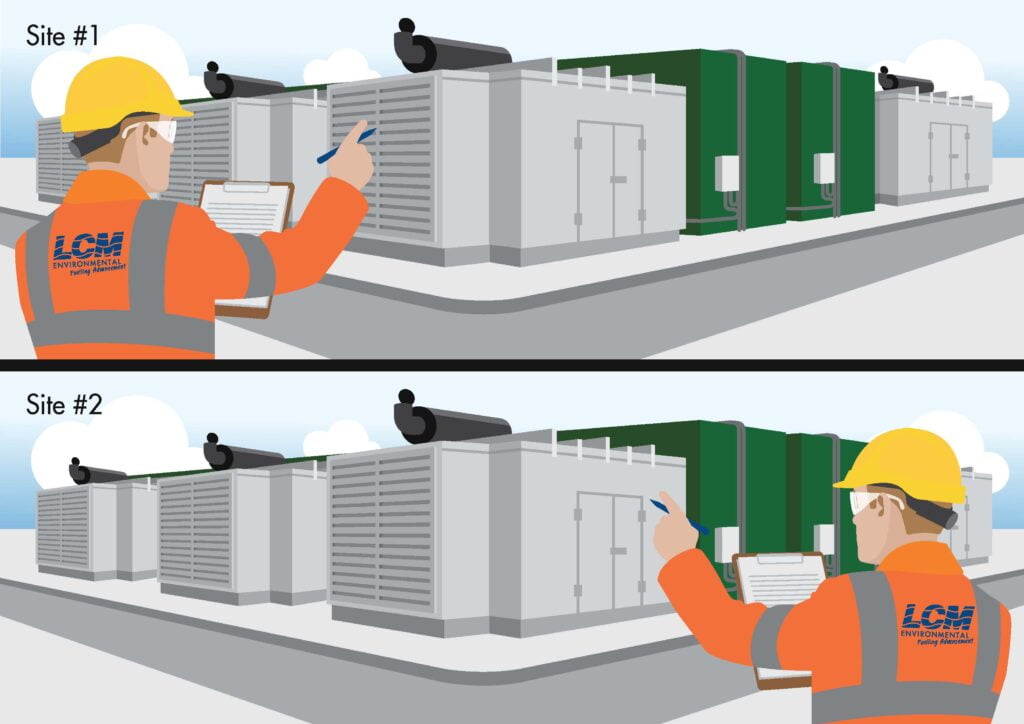

The LCM team surveyed 2 sites to report any potential challenges to the switchover, prepared a plan of action and put forward a proposal with an exact time scale and budget for the undertaking. The two sites with 42 rectangular above-ground tanks in total held a total capacity of 1.134 million litres.

Scope of Works

Two of the LCM engineers arrived on site and did their respective site surveys to ensure the tanks were accessible to tankers and safe to be man-entry cleaned. Fuel samples were also removed from the existing fuel stock to agree on an appropriate rebate with the client.

Reporting to the data centre manager, a detailed report was prepared, and a proposal was sent to the client. After careful consideration, the plan was finalised with the data centre and the works were scheduled in.

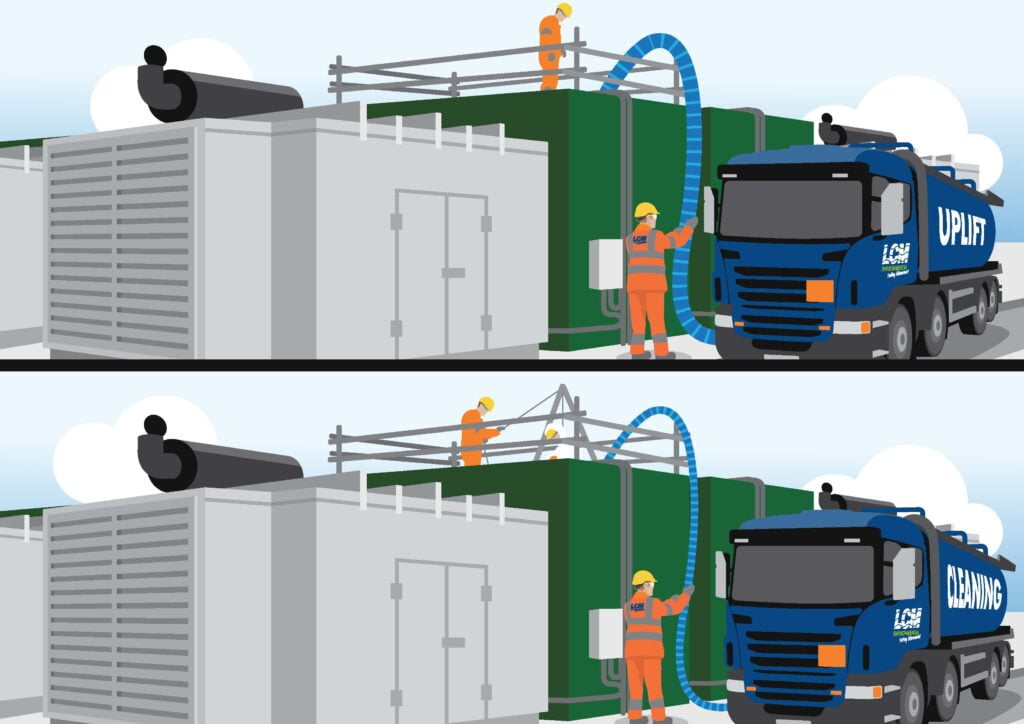

Step one was sending out a team with HGV tankers to uplit the fuel from fuel tanks one at a time. Tank by tank, the following procedure was executed:

- Each tank was uplifted individually to ensure the resilience of the data centre. The uplift tankers remained on site whilst the tank cleaning was completed to ensure that the site has sufficient fuel in case of a power outage.

- Once the gas oil was uplifted, it was tested for impurities. This client kept his fuel up to specification and LCM bought it from them, providing a rebate.

- A confined space team entered and cleaned it out of any gas oil residue, leaving the tank gas free.

- After the tank was declared gas free, a tank inspection team performed NDT testing to ensure the storage vessel was in good working order and with sufficient integrity. The pipework was then pressure tested to ensure its fit for purpose.

- If a tank failed an NDT inspection, a further proposal was put forward for the replacement or repair of the storage vessel.

-

- After ensuring that the tank is safe and compliant, the next step was supplying the HVO and transferring it into the tank.

- The client decided to pay-as-they-use the HVO, which is something LCM offers to their HVO clients. Instead of paying for the HVO in full, the client pays only for what they use.

The above-described process was repeated for all 42 tanks individually to ensure the continuous running of the data centre and maintain its resilience.

The Outcome

The data centre’s HVO switchover met the desired timescale and thanks to LCM’s pay-as-you-use scheme, the project funding was less than what was originally budgeted from the client. 1.05mL of fuel were uplifted and rebated, 42 tanks inspected and cleaned by our confined space rescue team, and 95% of the tanks’ capacity was filled with HVO, as per the client’s requirements.

Why HVO?

HVO (Hydrogenated Vegetable Oil) is a paraffinic diesel fuel compatible with all diesel engines. It is produced by the hydrotreatment of vegetable oils, grease waste, or residues from the food/agriculture industry and is made of 100% renewable raw materials.

HVO is the cleanest alternative fuel on the market that has been supercharged with an enhanced organic additive. It reduces CO2e by up to 90% and lowers greenhouse emissions significantly.

HVO Fuel does not contain FAME (Fatty acid methyl ester) and has a naturally high cetane number, which results in easy ignition and reduced smoke and particulates emissions. HVO is a 100% sustainable renewable paraffinic diesel substitute. It reduces harmful emissions of NOX and total particulate matter (TPM).