Start to finish design of fuel infrastructure services.

Our Fuel Infrastructure Services.

Our fuel infrastructure services ensure optimal fuel efficiency and seamless operations. We provide a full range of services, including design, installation, inspection, testing, and maintenance of fuel infrastructure, to help minimise risks, reduce costs, and prevent downtime.

With our expertise, your operations will meet both current and future capacity and compliance requirements.

Efficient and reliable installations.

Expert Tank Installation Team.

Our skilled workforce is trained to meet the standards required by OCTEL, HSE, and MOD SRP3. We have extensive experience in fuel tank and pipe installations, capable of handling projects ranging from one-off installations to full site decommissioning across the UK.

Bespoke designs made to suit your needs.

Tank Installations for Various Substances.

Our expertise allows us to meet the unique needs and demands of our clients. We can install and commission both metal and plastic tanks that hold various substances, including red and white diesel, kerosene, HFO, waste oil, water, solvents, hazardous waste, nitrogen, chlorine, and other chemicals.

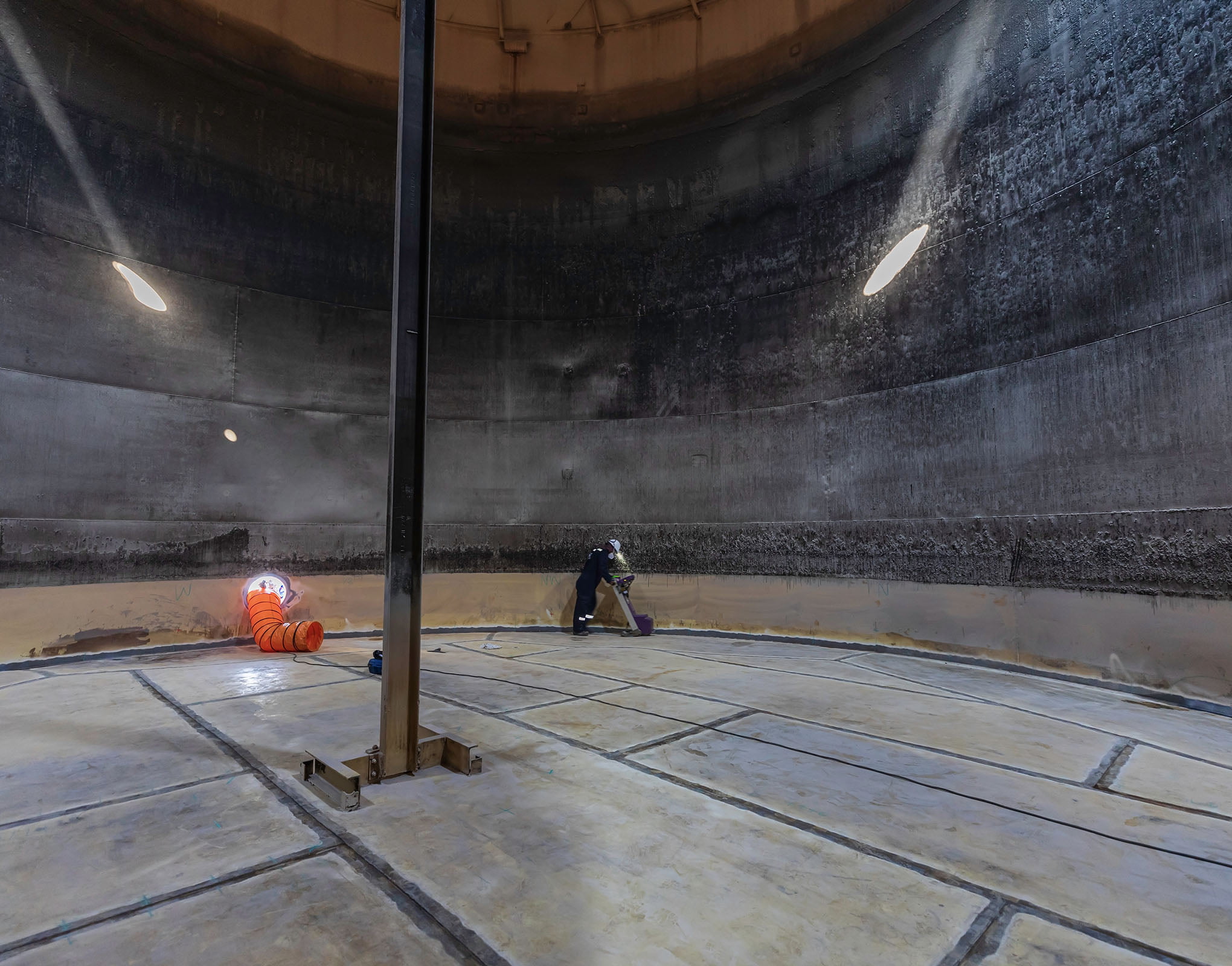

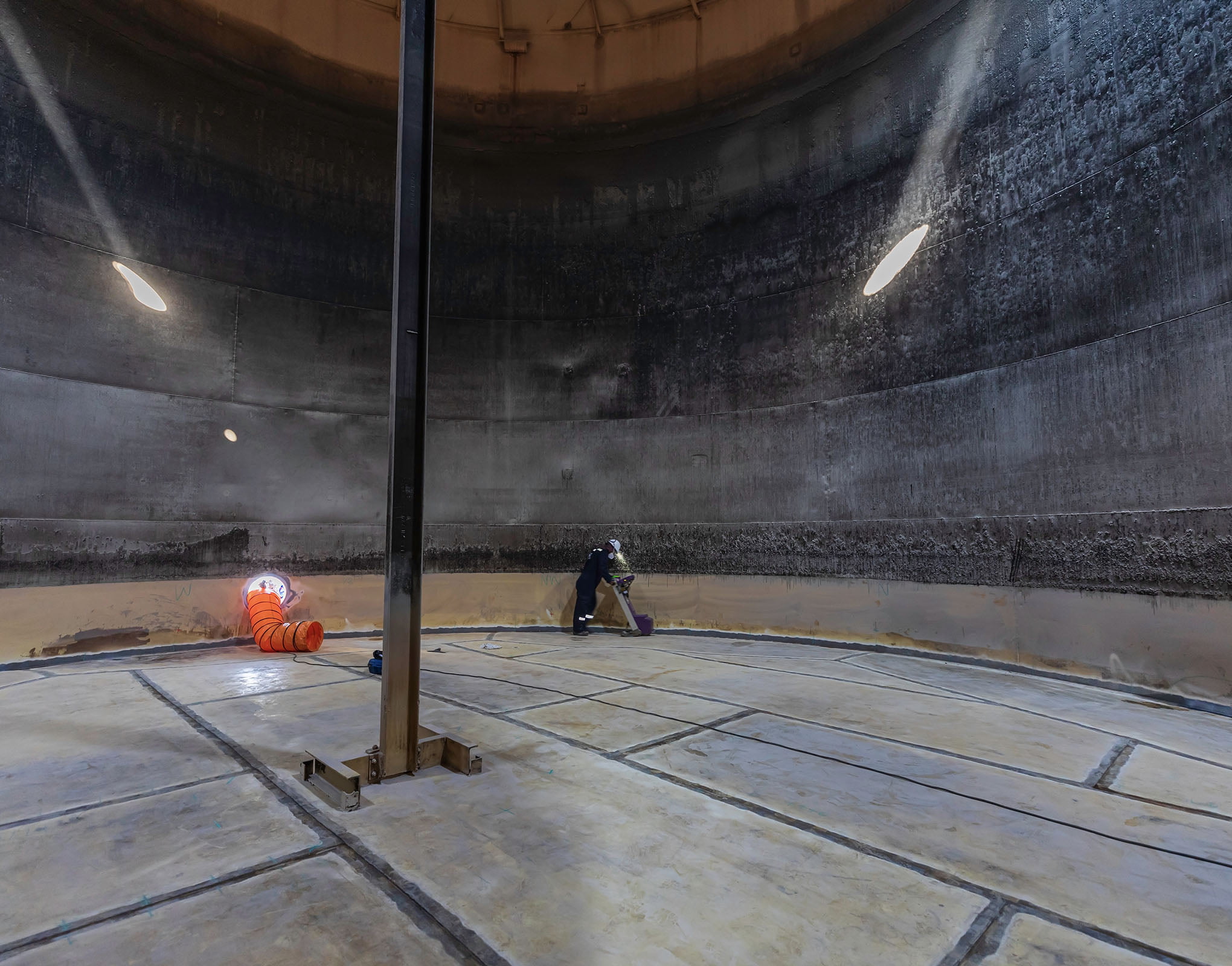

Storage Facility Decommission.

We can decommission tank storage facilities, including COMAH-registered infrastructure and above-ground or below-ground tanks, in compliance with regulations. Our services encompass fuel uplift, tank cleaning, potential tank cutting and removal, and subsequent civil works.

Tank Cleaning and Maintenance.

Tank cleaning protects against contamination and degradation, is recommended for compliance, and helps avoid pollution incidents, fines, and emergency spill costs. Our highly trained Confined Spaces Operatives adhere to strict health and safety measures when non-entry systems are impractical.

Renew tanks and the operational efficiency.

Save Your Tank From Decommission.

We offer internal repairs through a process called “tank-lining,” which involves creating a new, reinforced tank inside the old one using fibreglass and resin. This method, including options like single relines or dual-skin relines with an interstitial space for testing, is often the only way to extend the tank’s life, prevent corrosion, and stop leaks.

Preventative method to prolong tank life.

Protective Paint Application.

Additionally, we offer external solutions such as non-corrosive paint applications to protect fuel tanks from rust, ensuring durability and aesthetic appeal, with weather-resistant paint available in any colour.

Design and install custom designed infrastructure.

Custom-Engineered Fuel Infrastructure.

Our specialist teams understand that every site has its unique challenges, and design bespoke tanks to fit perfectly in any designated space. Whether you need a custom-engineered or standard-sized tank, above or below ground, cylindrical or rectangular, we deliver solutions that optimise space, ensure safety, and comply with all regulations.

Detailed solutions throughout each step.

Expert Design and Installation.

Our experts guide you through the entire process, from initial assessment to final installation, ensuring efficient fuel management and enhanced safety. Trust us to provide cost-effective designs that meet your specific needs and build the perfect fuel tank for your operation.

Mitigate risks for your fuel infrastructure.

Tank Testing and Inspections

Risk Mitigation

We focus on risk mitigation for fuel storage tanks, which typically have a life expectancy of 10-20 years, making integrity testing and maintenance crucial for ensuring their health and reliability.

Test, Clean and Repair Installations

The Health and Safety Executive recommends tank testing every 12-18 months to avoid issues like ground or watercourse contamination and damage to building structures. Neglecting tank maintenance can also jeopardise insurance coverage, our solutions include cleaning, repair, or decommissioning tanks, based on test results.

Expert Insights

Fuel storage regulations apply to heating fuel tanks, associated pipework, and bulk storage facilities. We will provide you with an OSR report, registered with OFTEC, that verifies whether your above-ground oil tank complies with current oil storage regulations, using principles based on DGSA, OFTEC 600A, Oil Storage Regulations, PPG2, and DSEAR 2002.

Non Destructive Testing

Non-destructive testing (NDT) is crucial for assessing the tank’s current condition and includes techniques such as tank thickness testing, base and weld testing, hardness testing, ultrasonic inspection, and UAV inspections. EEMUA 159 is a specialised test required by some insurers for large tanks, offering a comprehensive assessment of mechanical integrity to ensure tanks are safe for continued us.

Delivering maintenance solutions.

PPM Planned Preventative Maintenance.

We offer fully bespoke solutions for your fuel environment, delivered through both a robust planned preventative maintenance (PPM) service, and quality project management. The type of support, which is available within this service includes fuel testing, fuel cleaning, tank testing, automatic fuel top ups at 25% from empty, telemetry installation with a remote access portal, annual probe checks, bund and pipework inspections, provision of emergency spill kits and much more.

Industry standard craftmanship.

Comprehensive Pipework Solutions.

From installation to maintenance and repair, LCM offers comprehensive pipework solutions tailored to meet the specific needs of our clients. With a focus on quality craftsmanship and adherence to industry standards, we deliver durable and leak free piping systems essential for the efficient operation of facilities across diverse sectors.

Utilise the latest frameworks.

Tank Decommissioning.

We have extensive experience delivering decommissioning projects for large public sector clients like the Ministry of Defence, the Ministry of Justice, and the NHS, and as a Crown Commercial Services supplier, we help clients navigate procurement and utilise the latest frameworks.

Our values and promises.

Our Service Solutions.

With over 35 years of dedication to delivering reliable, sustainable, compliant solutions that reduce your risk and increase your peace of mind. It’s why we exist; to ensure the wheels of the world keep turning.

Keep up-to-date with LCM.

Our Blogs and Latest News.

Stay informed with the Latest News, explore our successful projects in Case Studies, and gain valuable insights and best practices in our Advice section. Discover how we lead in critical infrastructure, clean energy, and environmental services.