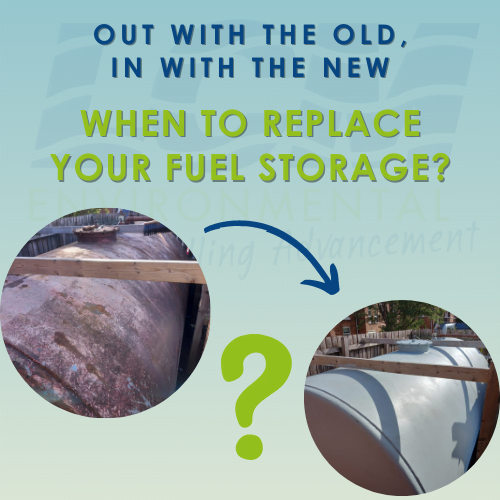

To replace, or not to replace – that is the question

We give you 3 signs your fuel storage is due for replacement – telltales that you should not ignore!

Your clean and functional fuel tanks are the backbone of your power and operations infrastructure – a crucial part in avoiding black starts, business downtime or a critical power outage. Despite being made to last, your tank storage equipment still lacks an infinite lifespan. Recognising the early signs of tear-and-wear can save you time, money, and unfortunate incidents involving environmental spillage.

Keep reading to find out when it’s time to end the Shakespearean dilemma, and ‘to replace’.

1. Steady structural ‘downhill’

Rust gathering, corrosion, visible cracks, and structural damage… if your fuel tank is starting to look like a WWII relic, it’s likely time for an upgrade. With age and environmental exposure, as well as the stored fuel corroding the vessel away from the inside, fuel storages tend to get ‘weaker’ and structurally more vulnerable.

The issue comes when the tank ‘gives’ and causes an environmental hazard – fuel leakage, chemical spills, ground contamination, spills into water bodies, potential total loss of a very expensive liquid asset – you name it! If the repairs on the tank are expensive, complex and cause more headaches than they heal, it should be clear – your fuel storage has reached its end of operational life and needs to be replaced.

Upgrading to modern equipment could be the answer to the safety and compliance concerns that have been plaguing your sites, trying to adapt old tanks to new standards!

2. Constant repairs and maintenance needs

If your fuel tank was a car, it would be in the garage more often than on the road? Do you find yourself frequently scheduling repairs and maintenance calls? It’s a giveaway that your fuel storage is at its end of life. The fuel vessel struggling to maintain functionality and incurring ongoing costs from repairs indicates that all components of its infrastructure are becoming less reliable.

A new tank is a significant upfront investment, much like a new car; the thing is, it pays off, long-term. Consider the cost of all repairs, business downtime, equipment failure consequences, and the risk of a potential fuel or chemical leak… Replacing your old fuel storage suddenly looks like the most cost-effective option!

3. Your fuel just won’t stay clean.

Do you find yourself having to filter your fuel a lot more often than before? Experiencing fuel quality issues could be a direct result of having deteriorating fuel storage; an ageing vessel won’t be effectively protecting your fuel from water build-up; sediment increase or debris accumulation. Deteriorating tanks are more prone to leakage and condensation build-up, which will inevitably ruin your fuel quality.

Replacing your ancient fuel storage with one from this era can ensure your site has the newest fuel filtration technology installations, moisture control mechanisms, better ventilation, leakage alarms and a full telemetry system to keep an eye on condensation buildup and fuel levels. This would facilitate your equipment operation and extend the lifespan of your machinery.

If your tank exhibits some or all of the above, your dilemma is solved. The answer is – ‘to replace’.

Despite being firm believers that most things can be saved (demonstrated by our fuel polishing, tank relining and tank repair services), at LCM, we would always advise you on the best and most cost-effective course of action. Having a tank with structural deterioration, that needs frequent repairs and ruins the quality of your fuel will cost you dearly, long-term.

Investing in a new fuel vessel will mitigate the risk of a potential fuel or chemical spill and will spare your business any unwarranted downtime and reputational damage.

To have us inspect your fuel storage and recommend an appropriate course of action, you can find our team at…

T: 0808 164 4570